橡膠輪

橡膠輪

橡膠輪

橡膠輪

輕型腳輪

2-1/2”x 7/8 活動煞車輪

型號: T-01

2-1/2”x 7/8 Swivel Caster w/Brake

東鉝實業股份有限公司

電話:04-723-2230

傳真:04-723-6990

彰化市桃源街25巷7號

實心橡膠輪:這種輪胎是由純橡膠或聚氨酯製成,無需充氣,並且非常耐用。這些輪胎通常用於手推車、推車和工業設備上。

彈性輪胎:這種輪胎是一種特殊的固體橡膠輪,由彈性橡膠製成,具有良好的彈性和緩衝效果。這些輪胎通常用於堆高機、叉車和其他需要運輸貨物的工業車輛上。

高溫橡膠輪:這種輪胎是由耐高溫橡膠製成,可以承受高溫環境下的使用,例如烤爐、高溫烤箱和工業爐灶等場合。

聚氨酯橡膠輪:這種輪胎由聚氨酯材料製成,具有非常好的耐磨性、耐腐蝕性和耐油性。這些輪胎通常用於各種設備和工業車輛上。

橡膠輪在許多不同的應用中都非常常見,例如輪椅、機器人、辦公椅和運動器材等。無論是哪種應用,選擇正確的橡膠輪尺寸、形狀和硬度都非常重要,以確保最佳性能和耐用性。

橡膠輪

橡膠輪

橡膠輪

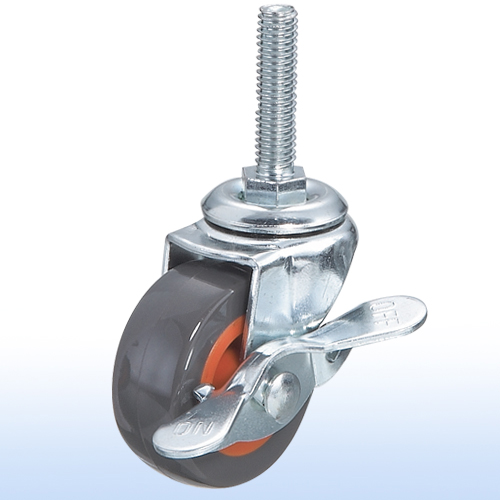

輕型腳輪

3”x 7/8 長桿活動煞車輪

型號: T-02

3”x 7/8 Extra-long-post Swivel Caster w/Brake

橡膠輪

橡膠輪是由橡膠製成的輪子,通常應用在各種不同的運輸工具、機械設備、家具、車輛等場合。橡膠輪的主要特點是具有良好的緩震降噪性能和適應性,這使得它們在許多場合中成為首選。

【主要特點與優勢】:

緩震降噪:橡膠輪具有較好的彈性和緩衝性能,能夠有效吸收地面震動和噪音,減少運輸和運動過程中的振動和聲響。

適應性強:橡膠輪能適應多種地面狀況,包括平整地面、不平整地面、堅硬地面和柔軟地面,因此適用範圍廣泛。

輕巧靈活:相對於金屬輪子,橡膠輪較為輕巧,使得機器設備和運輸工具更靈活和易於操作。

不損傷地面:橡膠輪的柔軟性使其不易對地面造成損傷,適用於各種地板表面,特別是對於木質地板和瓷磚地面等較脆弱的地面。

【應用場景】:

橡膠輪廣泛應用於各個領域,常見的應用場景包括但不限於以下:

物流運輸:橡膠輪常用於手推車、平台車、堆高機、搬運車等,用於方便地運輸各種物品,尤其是在倉庫、物流中心和生產線上。

家具:橡膠輪經常用於家具的腳輪,如椅子、桌子、辦公家具等,使家居環境中的家具更容易移動。

工業設備:橡膠輪廣泛用於工業設備,例如工作台、機器設備、車間工具等,提供方便的移動和操作。

醫療設備:在醫療行業中,橡膠輪常用於醫療床、輪椅、醫療器械等,確保醫療設備的靈活性和舒適性。

【選擇與注意事項】:

選擇橡膠輪時,需要根據具體應用場景和需求來進行選擇,並注意以下事項:

負載限制:根據橡膠輪的負載能力選擇合適的輪子,不要超過其承載能力,以避免橡膠輪損壞或使用不當導致安全問題。

地面狀況:在選擇橡膠輪時,要考慮工作環境的地面狀況,以確保橡膠輪能夠順利運行。

材質:不同的橡膠輪材料適用於不同的環境和用途,如耐油、耐化學藥品等。

定期檢查:定期檢查橡膠輪的狀況,特別是輪胎部分,確保沒有磨損、裂紋或其他損壞。

總體來說,橡膠輪的特點使其在許多應用場所中都得到廣泛使用。在選擇和使用橡膠輪時,要根據具體的應用需求和場所條件,合理選擇輪子的尺寸和材質,確保其良好的性能和壽命。同時,在使用過程中,定期檢查和保養橡膠輪,注意安全使用,也是非常重要的。

橡膠輪

橡膠輪

橡膠輪

輕型腳輪

2”x 7/8 活動煞車輪

型號: T-03

2”x 7/8 Swivel Caster w/Brake

為了確保橡膠輪的良好性能和長久使用,定期的維護與保養是必不可少的。以下是一些關鍵的維護措施:

清潔:定期清潔橡膠輪,特別是在使用環境較骯髒或塵土較多的場合。保持輪胎和輪輞的清潔,可以防止灰塵和污垢累積,影響運轉和摩擦效果。

定期檢查:定期檢查橡膠輪的狀況,特別是輪胎的磨損和裂紋情況。如果發現磨損或損壞,應及時更換,以避免輪胎在使用過程中突然損壞造成安全風險。

避免過載:避免將輪子用於超出其承載能力的負載,這可能會造成橡膠輪的損壞和變形。

避免長時間停留在潮濕或潛在腐蝕環境:橡膠輪如果長時間停留在潮濕的環境中,可能會影響其性能,甚至導致腐蝕。因此,在潮濕的環境下,應該避免長時間停留。

【橡膠輪與其他材質輪子的比較】:

在選擇輪子時,橡膠輪與其他材質輪子相比具有一些優勢和劣勢:

橡膠輪與金屬輪:相比金屬輪,橡膠輪具有更好的緩震降噪性能,不會對地板造成傷害,適用於一些對地板保護要求較高的場所。然而,橡膠輪的承載能力通常較金屬輪較低。

橡膠輪與尼龍輪:相比尼龍輪,橡膠輪具有更好的彈性,能夠適應不平坦的地面,而尼龍輪則更適合於平滑地板上的運動。

橡膠輪與聚氨酯輪:相比聚氨酯輪,橡膠輪的價格通常較為經濟,但聚氨酯輪擁有較高的承載能力和耐磨性。

【結論】:

橡膠輪作為一種常見的工業用輪,具有良好的緩震降噪性能和適應性,廣泛應用於各種場合。在使用橡膠輪時,定期的維護和保養是確保其良好性能和長壽命的關鍵。同時,在選擇輪子時,需要根據具體的應用需求和環境特點,選擇合適的輪子材質和規格。透過科學合理的選擇和正確的使用,橡膠輪將持續發揮其重要的運輸和運作功能,為各行業帶來便利和效益。

橡膠輪

橡膠輪

橡膠輪

輕型腳輪

2-1/2”x 7/8 長板活動煞車輪

型號: T-04

2-1/2”x 7/8 Swivel Caster w/Strip Brake

隨著科技的不斷發展,橡膠輪也在不斷進步和創新,以滿足不斷變化的需求和應用場景。以下是橡膠輪的一些進步與創新:

高性能橡膠材料:傳統的橡膠材料已經得到改良和優化,研發出更多高性能的橡膠材料。這些材料可以提供更優越的耐磨性、抗油性、耐高溫性等特性,使橡膠輪在各種極端環境下都能表現出色。

智能化應用:橡膠輪與智能技術的結合,使得橡膠輪可以實現自動監測和遠程控制。例如,在物流運輸中,橡膠輪配備智能傳感器,能夠實時監測負載狀態、地面狀況和輪子狀態,實現更智能的運輸和管理。

無軌迹設計:一些新型的橡膠輪設計採用了無軌迹結構,能夠減少地面擦痕,提高輪子在地面上的滾動靈活性。

環保和可持續性:一些橡膠輪製造商注重環保和可持續性,開發出可回收、可再生的橡膠材料,並提倡綠色生產和綠色應用,以減少對環境的影響。

定制化服務:隨著客戶需求的多樣化,一些橡膠輪製造商提供定制化服務,根據客戶的具體需求和應用場景,提供量身定制的橡膠輪產品。

【挑戰與解決方案】:

雖然橡膠輪不斷進步與創新,但仍然面臨一些挑戰,以下是一些常見的挑戰及相應的解決方案:

承載能力限制:相比金屬輪,橡膠輪的承載能力通常較低。解決方案包括使用高強度和高性能的橡膠材料,以提高輪子的承載能力。

耐磨性:橡膠輪在長時間高負載和高頻使用情況下,容易受到磨損。解決方案包括使用耐磨性較好的橡膠材料,以及定期檢查和更換磨損嚴重的輪子。

環境適應性:不同應用場所對橡膠輪的性能要求各異,對於特殊環境,如高溫、低溫、潮濕等,需要選擇適合的橡膠材料。解決方案包括開發特殊材質的橡膠輪,以應對特殊環境需求。

總體而言,橡膠輪作為一種重要的工業用輪,不斷進步與創新,應用範圍不斷擴大。在面臨挑戰時,透過科技創新和持續研發,橡膠輪將繼續發揮其重要的運輸和運作功能,為現代工業和生活帶來更多便利和效益。

橡膠輪

橡膠輪

橡膠輪

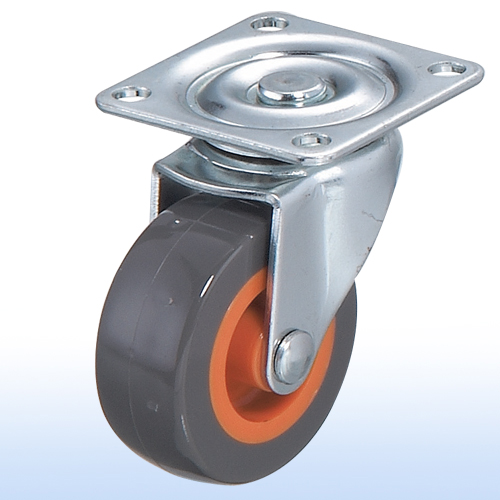

輕型腳輪

2”x 7/8 平板活動輪

型號: T-05

2”x 7/8 Flat-plate Swivel Caster w/Brake

隨著科技的不斷發展和應用需求的變化,橡膠輪在未來有望繼續取得進步和創新,展現更多潛力和功能。以下是橡膠輪的未來展望:

智能化與自動化:隨著智能技術的普及和應用,橡膠輪將更多地與智能裝置和自動化系統相結合。橡膠輪將成為具有感知、控制和自主運動能力的裝置,實現更高效、智能的運輸和操作。

材料創新:未來將不斷研發更先進的橡膠材料,以提高橡膠輪的性能和耐用性。新型材料可能具有更優越的耐磨性、抗油性、耐高溫性和耐化學性能,從而擴大橡膠輪的應用範圍。

環保與可持續性:未來將更加關注橡膠輪的環保性能和可持續性。推動使用綠色、可回收、可再生的橡膠材料,並加強回收再利用舊輪子,以減少對環境的影響。

設計創新:在設計上,未來的橡膠輪可能會更加注重實用性和人性化。設計更符合人體工學的輪胎形狀和手柄,提供更舒適的使用體驗。

多功能輪子:未來的橡膠輪可能會集成更多功能,例如電動助力、遙控操控、折疊收納等,使其更具多樣化的應用場景。

【對社會的影響】:

橡膠輪的進步和創新將對社會產生多方面的影響:

提高工作效率:智能化和自動化的橡膠輪將能夠更高效地進行運輸和操作,提高生產效率和工作效率。

降低能耗:更先進的材料和技術可以降低橡膠輪的能耗,減少能源浪費,對能源環保具有積極作用。

促進創新產業發展:橡膠輪的創新將促進相關產業的發展,如智能裝置制造、橡膠材料研發等,帶動產業升級和轉型。

提升生活品質:橡膠輪的改進將影響人們的生活方式,提供更方便、舒適的家居環境和日常工具。

總體來說,橡膠輪作為一種基礎的工業元件,在未來將繼續受到重視並得到不斷改進和創新。透過科技進步和環保意識的提高,橡膠輪將更好地適應社會需求,為各行各業帶來更多的便利和效益。

橡膠輪是由橡膠材料制成的輪子,通常用于車輛、機器和設備中的運動部件,以減少摩擦和震動。橡膠輪可分為實心橡膠輪和充氣橡膠輪兩種類型。實心橡膠輪通常由一塊實心橡膠制成,用于較小的載重和速度較慢的應用中。橡膠輪具有耐磨、耐油、耐腐蝕等優點,是許多應用中的理想選擇

橡膠輪是一種常見的車輪類型,它是由橡膠材料製成的圓形結構,通常在其周圍具有紋理或花紋,以增加其抓地力。而實心橡膠輪是指輪胎內部沒有充氣空間的一種橡膠輪子,因為它們不需要充氣,所以在某些應用中比充氣輪更適合,例如需要承受重量和耐磨的應用。

實心橡膠輪主要用於推車、手推車、叉車等載重工具的車輪上,因為它們能夠承受較大的負載,並且不需要定期檢查和充氣,減少了維護的時間和成本。此外,實心橡膠輪也可以用於工業機械設備、農業機械和建筑機械等領域。

儘管實心橡膠輪有許多優點,但它們也有一些缺點。例如,與充氣輪相比,它們的運動和減震能力較差,所以在某些應用中可能會影響操作的平穩度。此外,在不平坦的地面上行駛時,實心橡膠輪會比充氣輪產生更多的震動和噪音。

橡膠輪的特性、應用與市場趨勢

一、橡膠輪的基本概念

橡膠輪是一種廣泛應用於工業、商業及日常生活的輪子類型,主要由橡膠製成,並配合不同的輪架與軸承設計,以滿足各種負載與環境需求。由於橡膠具有良好的彈性、減震性與耐磨性,因此橡膠輪能有效降低震動與噪音,保護地面並提升移動設備的穩定性。

橡膠輪可依照不同的需求分為實心橡膠輪與充氣橡膠輪:

實心橡膠輪:由整塊橡膠製成,耐磨且不易刺破,適合重工業、倉儲、物流等領域。

充氣橡膠輪:內含氣體,能提供更好的減震效果,適合崎嶇不平的地面,如建築工地、農業機械等。

二、橡膠輪的優勢與特性

橡膠輪因其優異的物理特性,被廣泛應用於不同領域。主要優勢包括:

良好的減震與緩衝效果

橡膠具有出色的彈性,可以有效吸收震動,減少設備受到的衝擊力,特別適用於運輸精密儀器或易碎品。

降低噪音

與金屬輪、塑膠輪相比,橡膠輪在行駛時能有效降低噪音,使工作環境更安靜,適用於醫療設備、辦公設備等需要靜音的場合。

保護地面

由於橡膠具有一定的柔軟性,能夠減少對地面的磨損,適合使用於木地板、大理石等精緻地面,不易留下刮痕。

耐用且承重力適中

橡膠輪具有良好的耐磨性與一定的承載能力,能適應長時間使用,特別適合中等負載需求的行業,如物流倉儲、超市貨架等。

適應多種環境

橡膠輪能夠適應不同的地形,如室內光滑地面、戶外粗糙地面或潮濕環境,並且部分橡膠輪可具備抗油污、抗腐蝕等特性,適合工業環境使用。

三、橡膠輪的主要應用領域

工業設備

橡膠輪廣泛應用於工業推車、物流搬運設備、工廠生產線等場景,能夠提升設備的移動效率,並減少搬運過程中的震動損害。

醫療與商業設備

由於橡膠輪的靜音特性,常被應用於醫療推車、病床、超市購物車、飯店行李推車等,確保行駛過程順暢且不影響周圍環境。

建築與農業機械

在崎嶇或不平整的地面上,充氣橡膠輪能有效提升移動穩定性,適用於建築工地的設備、農業機械如拖車、耕耘機等。

運動與娛樂設備

橡膠輪亦應用於滑板、滑輪鞋、嬰兒推車、健身器材等,提供良好的抓地力與舒適的騎乘體驗。

四、橡膠輪的市場需求與未來發展趨勢

隨著全球工業與物流產業的發展,橡膠輪的市場需求持續增加,未來幾年將呈現以下趨勢:

環保與可持續發展

環保意識提升後,製造商開始研發可回收或可生物降解的橡膠材料,以降低對環境的影響。此外,使用低污染的生產工藝也成為趨勢之一。

高性能材料與技術創新

隨著科技進步,許多企業開始開發更耐磨、更耐高溫或更具特殊功能的橡膠輪,如防靜電橡膠輪、耐油橡膠輪,以滿足特殊產業的需求。

智能化與自動化應用增加

在自動化物流與智慧工廠中,橡膠輪將與感應技術結合,例如用於自動引導車(AGV)、機器人搬運系統等,提高物流效率。

客製化市場成長

由於不同產業的需求各異,企業越來越傾向於客製化橡膠輪,例如根據特定需求調整橡膠的硬度、耐磨性或耐高溫能力,以符合特定應用場景。

五、選購橡膠輪時的考量因素

在選擇橡膠輪時,應考慮以下幾個因素,以確保最佳的使用效果:

承載能力:根據設備的重量選擇合適的橡膠輪,以避免輪子變形或損壞。

使用環境:若需在潮濕或油污環境下使用,應選擇防滑、防油的特殊橡膠輪。

輪徑與寬度:較大的輪徑能提供更好的移動性能,而較寬的輪胎則能增加穩定性與承載力。

固定式或萬向式:固定式輪子適合直線移動,而萬向輪則能提高靈活性,需根據設備的運行需求選擇。

六、結論

橡膠輪因其良好的減震、靜音、耐磨與保護地面的特性,在各行各業中扮演著重要角色。隨著科技發展與市場需求變化,橡膠輪的應用範圍將持續擴大,並向高性能、環保與智能化方向發展。在選購橡膠輪時,企業應根據實際需求選擇合適的類型與規格,以提升設備的運

Characteristics, Applications, and Market Trends of Rubber Wheels

I. Basic Concepts of Rubber Wheels

Rubber wheels are a type of wheel widely used in industry, commerce, and daily life. They are primarily made of rubber and feature different wheel frames and bearing designs to meet various load and environmental requirements. Due to rubber's excellent elasticity, shock absorption, and wear resistance, rubber wheels effectively reduce vibration and noise, protect the ground, and improve the stability of mobile equipment.

Rubber wheels can be divided into solid rubber wheels and pneumatic rubber wheels according to different needs:

Solid rubber wheels: Made from a single piece of rubber, they are wear-resistant and puncture-resistant, suitable for heavy industry, warehousing, logistics, and other fields.

Pneumatic rubber wheels: Containing gas, they provide better shock absorption and are suitable for uneven surfaces, such as construction sites and agricultural machinery.

II. Advantages and Characteristics of Rubber Wheels

Rubber wheels are widely used in various fields due to their excellent physical properties. Key advantages include:

Excellent shock absorption and cushioning effect

Rubber has excellent elasticity, which can effectively absorb vibration and reduce the impact force on equipment, making it particularly suitable for transporting precision instruments or fragile items. Noise Reduction

Compared to metal and plastic wheels, rubber wheels effectively reduce noise during operation, creating a quieter working environment. They are suitable for applications requiring quiet operation, such as medical equipment and office equipment.

Floor Protection

Due to the flexibility of rubber, it reduces wear and tear on surfaces, making it suitable for delicate flooring such as wood and marble, and less prone to scratches.

Durable and with Moderate Load Capacity

Rubber wheels offer good wear resistance and a certain load-bearing capacity, making them suitable for long-term use. They are particularly well-suited for industries with medium load requirements, such as logistics warehousing and supermarket shelves.

Adaptable to Various Environments

Rubber wheels can adapt to different terrains, such as smooth indoor floors, rough outdoor floors, or damp environments. Some rubber wheels also possess oil and corrosion resistance properties, making them suitable for industrial environments.

III. Main Application Areas of Rubber Wheels

Industrial Equipment

Rubber wheels are widely used in industrial trolleys, logistics handling equipment, and factory production lines, improving equipment movement efficiency and reducing vibration damage during handling.

Medical and Commercial Equipment

Due to their quiet operation, rubber wheels are commonly used in medical carts, hospital beds, supermarket shopping carts, and hotel luggage carts, ensuring smooth movement without disturbing the surrounding environment.

Construction and Agricultural Machinery

On rough or uneven terrain, inflatable rubber wheels effectively improve stability, making them suitable for construction site equipment and agricultural machinery such as trailers and tillers.

Sports and Recreation Equipment

Rubber wheels are also used in skateboards, roller skates, strollers, and fitness equipment, providing good grip and a comfortable riding experience.

IV. Market Demand and Future Development Trends of Rubber Wheels

With the development of global industry and logistics, the market demand for rubber wheels continues to increase. The following trends are expected in the coming years:

Environmental Protection and Sustainable Development

With increased environmental awareness, manufacturers are beginning to develop recyclable or biodegradable rubber materials to reduce environmental impact. Furthermore, the use of low-pollution production processes is also becoming a trend.

High-Performance Materials and Technological Innovation

With technological advancements, many companies are developing rubber wheels that are more wear-resistant, heat-resistant, or have specialized functions, such as anti-static and oil-resistant rubber wheels, to meet the needs of specific industries.

Increasing Applications of Intelligent and Automated Systems

In automated logistics and smart factories, rubber wheels will be combined with sensing technologies, for example, in Automated Guided Vehicles (AGVs) and robotic handling systems, to improve logistics efficiency.

Growth of the Customization Market

Due to the diverse needs of different industries, companies are increasingly inclined to customize rubber wheels, such as adjusting the hardness, wear resistance, or heat resistance of the rubber to meet specific application scenarios.

V. Factors to Consider When Purchasing Rubber Wheels

When selecting rubber wheels, the following factors should be considered to ensure optimal performance:

Load Capacity: Select appropriate rubber wheels based on the weight of the equipment to avoid wheel deformation or damage.

Operating Environment: If use in humid or oily environments, choose special anti-slip and oil-resistant rubber wheels.

Wheel Diameter and Width: Larger wheel diameters provide better mobility, while wider tires increase stability and load-bearing capacity.

Fixed or Swivel-Type: Fixed wheels are suitable for linear movement, while swivel wheels improve flexibility; the choice should be based on the equipment's operational requirements.

VI. Conclusion

Rubber wheels play an important role in various industries due to their excellent shock absorption, quiet operation, wear resistance, and ground protection properties. With technological advancements and changing market demands, the application scope of rubber wheels will continue to expand, developing towards high performance, environmental friendliness, and intelligentization. When purchasing rubber wheels, companies should select the appropriate type and specifications based on actual needs to improve equipment operation.